Andian-teny tokana efatra mifandraika amin'ny baolina matotra

-

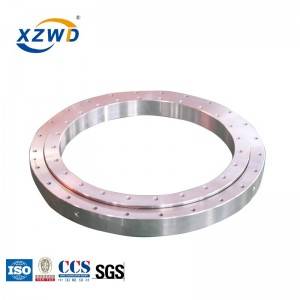

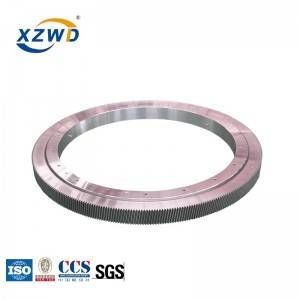

Fitaovana singam-pandeha ivelany ivelany misy teboka efatra teboka 011 Series Series Series

Izahay dia mpanamboatra ambony amin'ny peratra matevina isan-karazany.

Nandalo ISO9001: 2015. Miaraka amin'ny kalitao mitovy amin'ny marika malaza hafa.

Raha miara-miasa aminay ianao, dia afaka mamonjy ny vidinao noho ny vidiny dia tena mifaninana.

-

Ny teboka 4 isa avo lenta dia mifandray amin'ny ball kurbine amin'ny rivotra

Ny turbin-drivotra dia karazana angovo maitso sy maharitra. Ny fiantsoana sy ny fantsom-bolo sy ny fanamboarana dia misy ampahany lehibe amin'ny mpamokatra turbines rivotra, manampy ny Blades Rotor fa mihodina mora foana amin'ny rivotra ary manova ny angovo kinetika amin'ny herin'ny herinaratra.

Mampiasa ny rafi-pitaovana manokana izahay ary manome tery tanteraka ary manolo-kevitra koa ny fitoniana miaraka amin'ny rafitra lubrication.

-

Xzwd efatra teboka nifanerasera tamin'ny baolina natambatra

Ny famonosana peratra, na ny halavam-bidy, na ny turntable, dia ny bas na roller style bearings izay misy peratra misy concentric roa izay mety hisy fitaovam-piadiana. Ity karazana fampivoarana ity dia manatsara ny fanohanana sy ny fifindran'ny herinaratra amin'ny lafiny rehetra, ary mazàna ampiasaina amin'ny fanohanana entana mavesatra ho an'ny fangatahana miadana sy fitaovana lehibe toy ny fiparitahana amin'ny tany sy ny vanona fananganana. Ny herinaratra sy ny marim-pototra miavaka dia nahatonga azy ireo ho sarobidy amin'ny indostria maro be, ao anatin'izany ny fananganana, ny indostria, ny robotika, ny fitaovana milina ary ny fampiharana ara-pitsaboana.

-

Strongle vy anti-rust

inôksaSlewing Bearingsmanana hery sy fanoherana mahery vaika.

Ny fisafidianana ireo lubricants mety sy ny tombo-kase dia azo ampiasaina amin'ny -60 ℃ ~ + 300 ℃.

Ny stainless vy vy mivalona dia afaka manohitra ny korosion vokatry ny hamandoana sy ny haino aman-jery maro hafa.

-

Xzwd single row ball ball turntable peratra matevina

Ny fenitry ny fanamboarana antsika dia araka ny Grame-Machine Orse JB / T230000-2011, izahay koa dia nahita ny rafitra fitantanana kalitao tsara (qms) ao amin'ny ISO 9001: 2008 sy GB / t19001-2008. Manokana ny tenantsika amin'ny R & D ny matotra fanao amam-panao tsara isika miaraka amin'ny fepetra avo lenta, tanjona manokana sy takiana.

Mifantoka sy mifehy ny antsipirian'ny famokarana rehetra isika, ho an'ny fandefasana vokatra tsara amin'ny mpanjifa ihany.

Ny akora ny satroka matotra dia amin'ny alàlan'ny steel-stray-stray-stray-struktural, toy ny 42crmo, 50mn.

-

XZWD | China dia matotra tsara ho an'ny robots indostrialy maoderina

Xzwd slowing mitondra ny fanohanana lehibe amin'ny famonosana peratra ho an'ny mpiara-miasa tsirairay!

Miaraka ho fanarenana!

Azafady mba mifandraisa aminay raha manana fangatahana ianao.

Ny andian-tsolika XZWD dia manana ity andiany vokatra manaraka ity:

1.Mifidy tsipika efatra teboka nifandray tamin'ny baolina natory.

2.Ny laharana dia niampita roller slewing bearings

3.Ny Ball Ball Ball Slewing Bearings

4.Three row roller slewing bearings

Ehthin Sekric Slewing Bearings (karazana maivana).

6.Mampitambatra ny satroka matevina (karazana Flange)

-

Xzwd-po-po-po-po-po-po-po-point mifanila amin'ny vava miaraka amin'ny peratra tsy misy fotony

Mifantoka sy mifehy ny antsipirian'ny famokarana rehetra isika, ho an'ny fandefasana vokatra tsara amin'ny mpanjifa ihany.

Ny vokatra azo alaina ao anatin'izany: baolina tokana sy indroa, roller telo, Cross roller nasiana tombo-kase ary tsy hita taratra, namboarina ivelany sy ny fanadiovana ivelany na ny fanadiovana tsy misy fotony na preloaded.

Ny turntables sy ny peratra matotra dia atolotra amin'ny habe metric sy santimetatra miaraka amin'ny fahaizana manamboatra ny fifaneraserana mitangorona mba hanoratana ny fangatahana. Ny mampiavaka ny peratra maneno avy amin'ny turntables dia ny fidiran'ny nify gear amin'ny peratra anatiny na peratra anatiny.

-

Xzwd single single ball natolory ny fitaovam-piadiana ivelany ivelany ho an'ny milina mankaleo

Ny fenitry ny fanamboarana antsika dia araka ny Grame-Machine Orse JB / T230000-2011, izahay koa dia nahita ny rafitra fitantanana kalitao tsara (qms) ao amin'ny ISO 9001: 2008 sy GB / t19001-2008. Manokana ny tenantsika amin'ny R & D ny matotra fanao amam-panao tsara isika miaraka amin'ny fepetra avo lenta, tanjona manokana sy takiana.

Ny Xuzhou Wanda dia mamatotra ny karazana vokatra:

1.Mifidy tsipika efatra teboka nifandray tamin'ny baolina natory.

2.Ny laharana dia niampita roller slewing bearings

3dougouble Ball Ball Slewing Bearings

4.Three row roller slewing bearings

Ehthin Sekric Slewing Bearings (karazana maivana).

6.Mampitambatra ny satroka matevina (karazana Flange)

Xzwd Ny peratra matevina dia namboarina ho:

■Fitaovana fiantsoana efatra

-Ireo peratra matevina ireo tsy misy preload dia nopotehina ary voaporofo fa be dia be ny asa; Mametraka kely fotsiny ny fitakiana kely momba ny fisaka sy ny fahatongavan-tena amin'ny fananganana mifanila-Izy ireo dia mety amin'ny fampiharana amin'ny fepetra takiana ambany ho an'ny fahitsiana sy ny hakiviana ny fandaminana mitondra, ohatra, amin'ny milina vita amin'ny metaly tsotra, fitaovana herin'ny rivotra ary milina fanorenana

World Hot Sno World Hot Sale XZWD Four Point Contact Ball Ball Turntable Ping

Ny vokatra azo alaina ao anatin'izany: baolina tokana sy indroa, roller telo, Cross roller nasiana tombo-kase ary tsy hita taratra, namboarina ivelany sy ny fanadiovana ivelany na ny fanadiovana tsy misy fotony na preloaded.

Ny Xuzhou Wanda dia mamatotra ny karazana vokatra:

1.Mifidy tsipika efatra teboka nifandray tamin'ny baolina natory.

2.Ny laharana dia niampita roller slewing bearings

3.Ny Ball Ball Ball Slewing Bearings

4.Three row roller slewing bearings

Ehthin Sekric Slewing Bearings (karazana maivana).

6.Mampitambatra ny satroka matevina (karazana Flange)

No Gear ivelany Dimensions (MM) Fitaovana fametahana (mm) Ny refy struktural (mm) Data Gear Force10 ^ 4 kn lanja

kgD d H D1 D2 n Φ dm L n1 D3 d1 H1 h b x M De z N T 1 011.20.200 280 120 60 248 152 12 16 M14 28 2 201 199 50 10 40 0 3 300 98 1.5 2.1 24 2 011.20.224 304 144 60 272 176 12 16 M14 28 2 225 223 50 10 40 0 3 321 105 1.5 2.1 25 3 011.20.250 330 170 60 298 202 18 16 M14 28 2 251 249 50 10 40 0 4 352 86 2.1 2.8 30 4 011.20.280 360 200 60 328 232 18 16 M14 28 2 281 279 50 10 40 0 4 384 94 1.5 2.8 34 5 011.25.315 408 222 70 372 258 20 18 M16 32 2 316 314 60 10 50 0 5 435 85 2.9 4.4 52 6 011.25.355 448 262 70 412 298 20 18 M16 32 2 356 354 60 10 50 0 5 475 93 2.9 4.4 59 7 011.25.400 493 307 70 457 343 20 18 M16 32 2 401 399 60 10 50 0 6 528 86 3.5 5.3 69 8 011.25.450 543 357 70 507 393 20 18 M16 32 2 451 449 60 10 50 0 6 576 94 3.5 5.3 76 9 011.30.500 602 398 80 566 434 20 18 M16 32 4 501 499 498 70 10 60 0.5 5 629 123 3.7 5.2 85 012.30.500 6 628.8 102 4.5 6.2 10 011.30.560 662 458 80 626 494 20 18 M16 32 4 561 559 558 70 10 60 0.5 5 689 135 3.7 5.2 95 012.25 / 30.560 6 688.8 112 4.5 6.2 11 011.30.630 732 528 80 696 564 24 18 M16 32 4 631 629 628 70 10 60 0.5 6 772.8 126 4.5 6.2 110 012.25 / 30.630 8 774.4 94 6 8.3 / 8.2 12 011.30.710 812 608 80 776 644 24 18 M16 32 4 711 709 708 70 10 60 0.5 6 850.8 139 4.5 6.2 120 012.30.710 8 854.4 104 6 8.9 / 8.3 13 011.40.800 922 678 100 878 722 30 22 M20 40 6 801 798 90 10 80 0.5 8 966.4 118 8 11.1 220 012.40.800 10 968 94 10 14.1 / 14 14 011.40.900 1022 778 100 978 822 30 22 M20 40 6 901 898 90 10 80 0.5 8 1062.4 130 8 11.1 240 012.40.900 10 1068 104 10 14 15 011.40.1000 1122 878 100 1078 922 36 22 M20 40 6 1001 998 90 10 80 0.5 10 1188 116 10 14 270 012.30 / 40.1000 12 1185.6 96 12 16.7 16 011.40.1120 1242 998 100 1198 1042 36 22 M20 40 6 1121 1118 90 10 80 0.5 10 1298 127 10 14 300 012.30 / 40.1120 12 1305.6 106 12 16.7 17 011.45.1250 1390 1110 110 1337 1163 40 26 M24 48 5 1252 1248 100 10 90 0.5 12 1449.6 118 13.5 18.8 420 012.35 / 45.1250 14 1453.2 101 15.8 21.9 18 011.45.1400 1540 1260 110 1487 1313 40 26 M24 48 5 1402 1398 100 10 90 0.5 12 1605.6 131 13.5 18.8 480 012.35 / 45.1400 14 1607.2 112 15.5 21.9 19 011.45.1600 1740 1460 110 1687 1513 45 26 M24 48 5 1602 1598 100 10 90 0.5 14 1817.2 127 15.8 21.9 550 012.35 / 45.1600 16 1820.8 111 18.1 25 20 011.45.1800 1940 1660 110 1887 1713 45 26 M24 48 5 1801

18021798 100 10 90 0.5 14 2013.2 141 15.8 21.9 610 012.35 / 45.1800 16 2012.8 123 18.1 25 21 011.40 / 60.2000 2178 1825 144 2110 1891 48 33 M30 60 8 2001

20021998 132 12 120 0.5 16 2268.8 139 24.1 33.3 1100 012.40 / 60.2000 18 2264.4 123 27.1 37.5 22 011.40 / 60.2240 2418 2065 144 2350 2131 48 33 M30 60 8 2241

22422238 132 12 120 0.5 16 2492.8 153 24.1 33.3 1250 012.40 / 60.2240 18 2498.4 136 27.1 37.5 23 011.40 / 60.2500 2678 2325 144 2610 2391 56 33 M30 60 8 2501

25022498 132 12 120 0.5 18 2768.4 151 27.1 37.5 1400 012.40 / 60.2500 20 2776 136 30.1 41.8 24 011.40 / 60.2800 2978 2625 144 2910 2691 56 33 M30 60 8 2802 2798 132 12 120 0.5 18 3074.4 168 27.1 37.5 1600 012.40 / 60.2800 20 3076 151 30.1 41.8 25 011.50 / 75.3150 3376 2922 174 3286 3014 56 45 M42 84 8 3152 3147 162 12 150 0.5 20 3476 171 37.7 52.2 2800 012.50 / 75.3150 22 3471.6 155 41.5 57.4 Fanamarihana:

1. N1 no nofon-damba amin'ny holes.oil kaopy m10 × 1jb / t7940.1 ~ JB / T7940.2

2. N-φcan Changcan dia hiova hotsimpona, ny halavan'ny lavaka voafehy dia m, ny halaliny dia 2m.

3. Ny hery nify ara-tsarimihetsika amin'ny endrika dia ny herin'ny nify max, ny hery nifidy nomanina nomanina dia 1/2 ny ambony indrindra.

4. K "k" K "dia ny fampihenana ny Addendum.

Xzwd Ny peratra matevina dia namboarina ho:

■Fitaovana fiantsoana efatra

-Ireo peratra matevina ireo tsy misy preload dia nopotehina ary voaporofo fa be dia be ny asa; Mametraka kely fotsiny ny fitakiana kely momba ny fisaka sy ny fahatongavan-tena amin'ny fananganana mifanila -

Xzwd haingam-pandeha hafainganam-pandeha tokana tokana efatra misy teboka baolina

Ireo lavarangana ireo dia afaka manohana fotoana be dia be amin'ny toe-javatra rehefa tsy lavitra ny vesatra avy amin'ny Axis Central.

Ny turntables sy ny peratra matotra dia atolotra amin'ny habe metric sy santimetatra miaraka amin'ny fahaizana manamboatra ny fifaneraserana mitangorona mba hanoratana ny fangatahana. Ny mampiavaka ny peratra maneno avy amin'ny turntables dia ny fidiran'ny nify gear amin'ny peratra anatiny na peratra anatiny.

Mifantoha ary mifehy ny antsipiriany rehetra famokarana, ho an'ny fandefasana vokatra tsara amin'ny mpanjifa ihany.

Ny akora ny satroka matotra dia amin'ny alàlan'ny steel-stray-stray-stray-struktural, toy ny 42crmo, 50mn.

Ny akora ny rolls dia GCR15 ary novidy tamin'ny mpamatsy an-trano izay manana kalitao avo indrindra. -

Xzwd Diamet diameter tokana tokana polymer matavy

Ny andalana tokana efatra dia nifandray tamin'ny baolina matotra baolinaNy perings 2 seza dia misy endrika endrika sy hazavana amin'ny lanjany.

Azo ampiasaina amin'ny famatorana ny conveyer, ny fitaovam-piadiana sy ny sandry, ny jiro, ny adidy antonony, ny hazandrano ary ny milina injeniera hafa. -

XzWD | Manamboatra matihanina matihanina manamboatra ny robot Welding

Ny fampielezan-kevitra momba ny robots indostrialy amin'ny orinasa automatique dia nanatsara ny fahombiazan'ny famokarana famokarana. Ny mekanika fototra amin'ny robot indostrialy dia sandry mekanika. Ny famolavolana ara-barotra marobe amin'ny-fahalalahana dia mamela ny sandrin'ny robotic mba hanana haingam-pandeha be dia be. Afaka mahita ny teboka sy handroso araka ny fomba iray amin'ny alàlan'ny habakabaka. Ny mekanika mihodinkodina amin'ny sandry mekanika dia mampiasa cylinder hydraulic rotary na môtô servo mba hahatsapa ny hetsika mihodinkodina amin'ny alàlan'ny fametahana peratra matevina.

-

Slewing matihanina matihanina mpanamboatra ho an'ny Welding Positioner

Welding PositionersNatao hametrahana ny ampahany amin'ny toerana misy ny fiantsoana tsara indrindra amin'ny toerana misy azy.